In the highly specialized field of automotive door lock actuators, precision and quality are paramount. At the heart of Gleeful's success lies its state-of-the-art Mold Manufacturing Center. This facility embodies the company's commitment to producing top-tier car door lock actuators by leveraging advanced technology and meticulous craftsmanship.

Mold production is far from a straightforward mechanical process; it is a complex operation that demands both precise equipment and meticulous technology. At Gleeful, we understand that the quality of our molds directly influences the performance and durability of our car door lock actuators. Hence, we employ only the highest standards in mold manufacturing.

One of the cornerstones of our Mold Manufacturing Center is the use of high-quality steel in our standard molds. This choice ensures that our molds are robust and durable, capable of withstanding the rigorous demands of automotive manufacturing. Moreover, the precision of our molds ensures that each actuator component meets the exact specifications required for optimal performance.

Our facility is equipped with a range of cutting-edge machinery designed to facilitate the precise and intricate process of mold production. Among the equipment at our disposal are CNC milling machines (CNC), wire cutting machines, electric pulse machines, and grinding machines. Each piece of equipment plays a crucial role in the manufacturing process:

CNC Milling Machines (CNC): These machines allow for highly precise cutting and shaping of mold components, ensuring that each piece fits perfectly with minimal error margins.

Wire Cutting Machines: These are essential for creating intricate shapes and designs within the molds, enabling us to produce complex actuator components with high precision.

Electric Pulse Machines: Used for fine detailing and finishing touches, electric pulse machines ensure that the molds have the necessary detail and finish required for high-quality actuator production.

Grinding Machines: These machines are crucial for achieving the smooth finishes and exact dimensions needed for each mold, ensuring that every component produced is of the highest standard.

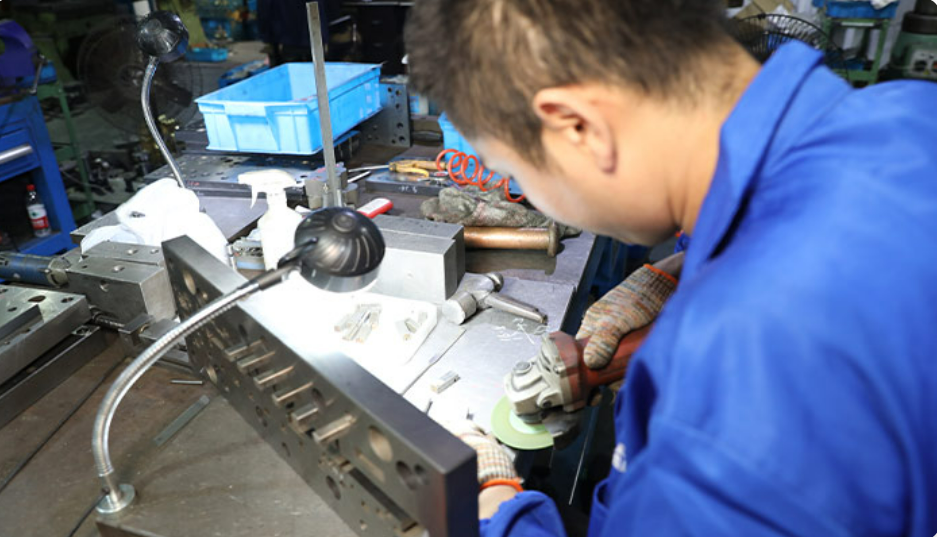

At Gleeful, we recognize that the success of our car door lock actuators is intrinsically linked to the quality of the molds from which they are produced. Our Mold Manufacturing Center not only houses advanced equipment but also employs a team of skilled technicians and engineers who bring meticulous attention to detail and a commitment to excellence.

By repeatedly investing in both our equipment and our personnel, Gleeful ensures that every actuator we produce meets the highest standards of quality and reliability. Our dedication to maintaining a cutting-edge Mold Manufacturing Center is a testament to our overarching goal: to provide our customers with the best car door lock actuators on the market.

In conclusion, Gleeful's Mold Manufacturing Center is a critical component of our production process, enabling us to maintain the highest levels of precision, quality, and reliability in our products. By combining advanced technology with expert craftsmanship, Gleeful continues to set the standard in the automotive door lock actuator industry.

GET A QUOTE